Greenhouse GrowerCutting-edge technology for new FlavourFresh glass

Read more

The happy sounds of clinking champagne glasses no doubt reverberated around Flavourfresh Group’s headquarters last month as the Merseyside-based tomato producer celebrated the completion of its 1 million pound state-of-the-art glasshouse.

This report is from Rachel Anderson.

Grower Andy Roe, who led the development from start to finish, proudly claims that it is one of the most energy efficient and modern glasshouses in Britain. This, he explains, is largely because cutting-edge Dutch technology played a large part in the project. He explains that Dalsem, which is based in Holland, supplied many of the materials as well as the contractors. Andy also attributes the successful completion of the project to the hard work of Lancashire-based specialist LS Systems, which won the tender to coordinate the project for the tomato grower. LS Systems therefore helped to select Dalsem for the job and worked closely with its Dutch-speaking contractors.

LS Systems sales director Darren McDonald, who managed the project form the initial civil works right through to the handover, says: “the people who worked for me have been building glasshouses all over Europe for a long time. And now they’ve done what they do in Europe right here in the North West of England. Andy adds that, once he had gained planning permission for the site, the process of selecting contractors and building the structure began a relatively short time ago, in late April last year. Given that the young plants, supplied by Yorkshire-based propagators Plant Raisers, were delivered into the newly finished building last month, on December 2, the project has run relatively smoothly and on schedule and on budget.” Darren says: “We have had three major elements (of the project) that have gone well; - good weather when we have been doing the building work; good contractors; and the fact that everything has gone well in terms of linking it together from LS Systems. We have not had many issues at all.”

Grower Andy Roe, who led the development from start to finish, proudly claims that it is one of the most energy efficient and modern glasshouses in Britain.

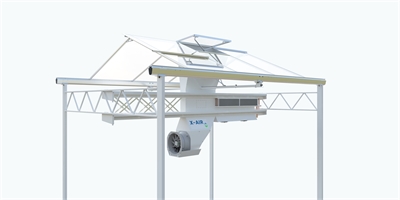

The 12.500 square metre structure, which has been built for year-round tomato production, has increased the firm’s overall growing facility by ten per cent. It also boasts several features that are new to Flavourfresh Group, including frameless vents in the roof of the glasshouse, energy efficient side screens, double grow tube heating and a diffused glass roof. Darren explains that the frameless vents improve light level transmission to the crop, while the side screens will improve energy efficiency during the coldest months of the year. The will also work in conjunction with the roof screening installed by subcontractor Holland Screening, another Dutch firm.

The new glasshouse also features thermal screens above the crop as well as a roof made out of diffuse, anti-reflection (AR) coated glass. Darren says: “The AR glass has many benefits. For example, it lets in a maximum amount of light but also reduces the temperature of the crop itself.”

Double grow tubes form part of the glasshouse’ new heating system, which sees a central boiler heat the water for its pipes. These “double” grow tubes are another new technology for Flavourfresh Group, and see two hot water pipes (rather than one pipe) positioned about half a metre apart and suspended within the crop. “This gives us a lot more heat and fluidity,” says Andy, who adds that the heating system, which was supplied and installed by Dalsem, also features heating pipes on the floor, “so there are both ground (heating) pipes and two (heating) pipes within the crop.”

Another Dutch firm, Formflex, supplied the suspended growing system for the nursery. The Netafim irrigation system, meanwhile, sees the irrigation water in the glasshouse collected, recirculated and therefore reused. A reservoir has also been built to house rainwater that is harvested from the roof of the new structure.

Andy hopes that by introducing all of these technologies into Flavourfresh Group’s latest addition, he will be helping to both reduce the firm’s energy bills and increase its tomato yields. He says: “We are expecting an energy saving of approximately 30 per cent minimum. The kg/m2 (output) will rise 25 per cent due to better light transmission and the ability to plant earlier. So we will now give this (glasshouse project) a full 12 months to see what the energy savings are.”

The glasshouse is growing just one tomato variety, Sweetelle- otherwise known as baby plum Santini. The plants are being grown hydroponically in coir that is supplied by Botanicoir – while Syngenta Bioline supplies the crop’s biocontrols. Andy is expecting his first tomato harvest in February. He jokingly says that the most exciting part of the project “will be in November 2015 – only then will I know just how well things have performed.” However, despite Andy’s high hopes for improved yields and reduced bills, he emphasises that, as the company’s name suggests, “Our main driver is the flavour of the tomatoes.” Flavourfresh Group, a privately-owned company that was formed by a group of three local growers 17 years ago, mainly grows tasty specialty tomato varieties such as baby plum and cherry tomatoes. “The team here have been growing tomatoes for over a quarter of a century for Marks and Spencer and Asda. We do not grow anything that is larger than the size of a golf ball,” explains Andy.

He adds that Flavourfresh Group has been growing Sweetelle (Santini) for some three years now, and the product continues to please consumers. Andy attribute’s Sweetell’s popularity to “its perfect size with a complementary balance of sweetness and acids.” He adds: “We cannot keep up with demand for our product. So we need to expand and modernise.” As more British growers begin to invest in new technologies and year-round production, this project heralds the continuing success of the UK’s tomato-growing industry.

Other people read

如果您有任何疑问,请与我们联络:

,

或致电:+31 (0)15 269 5800(前台)

我们很乐意为您服务。

Dalsem

Dalsem

Woudseweg 9 | 2635 CG Den Hoorn | The Netherlands | +31 (0) 15 2695800 |

-400-200.jpg)